CAM software

We use state-of-the-art CAM software to process customer data. This software allows us to verify the manufacturability of the board, prepare programs for individual manufacturing operations and automatically debug inaccuracies and design errors using DRC control.

The preferred and most reliable format for transferring gerber data is ODB++, but we are also able to work with older and less sophisticated formats such as Gerber 274X, X2, Eagle or possibly DXF contours.

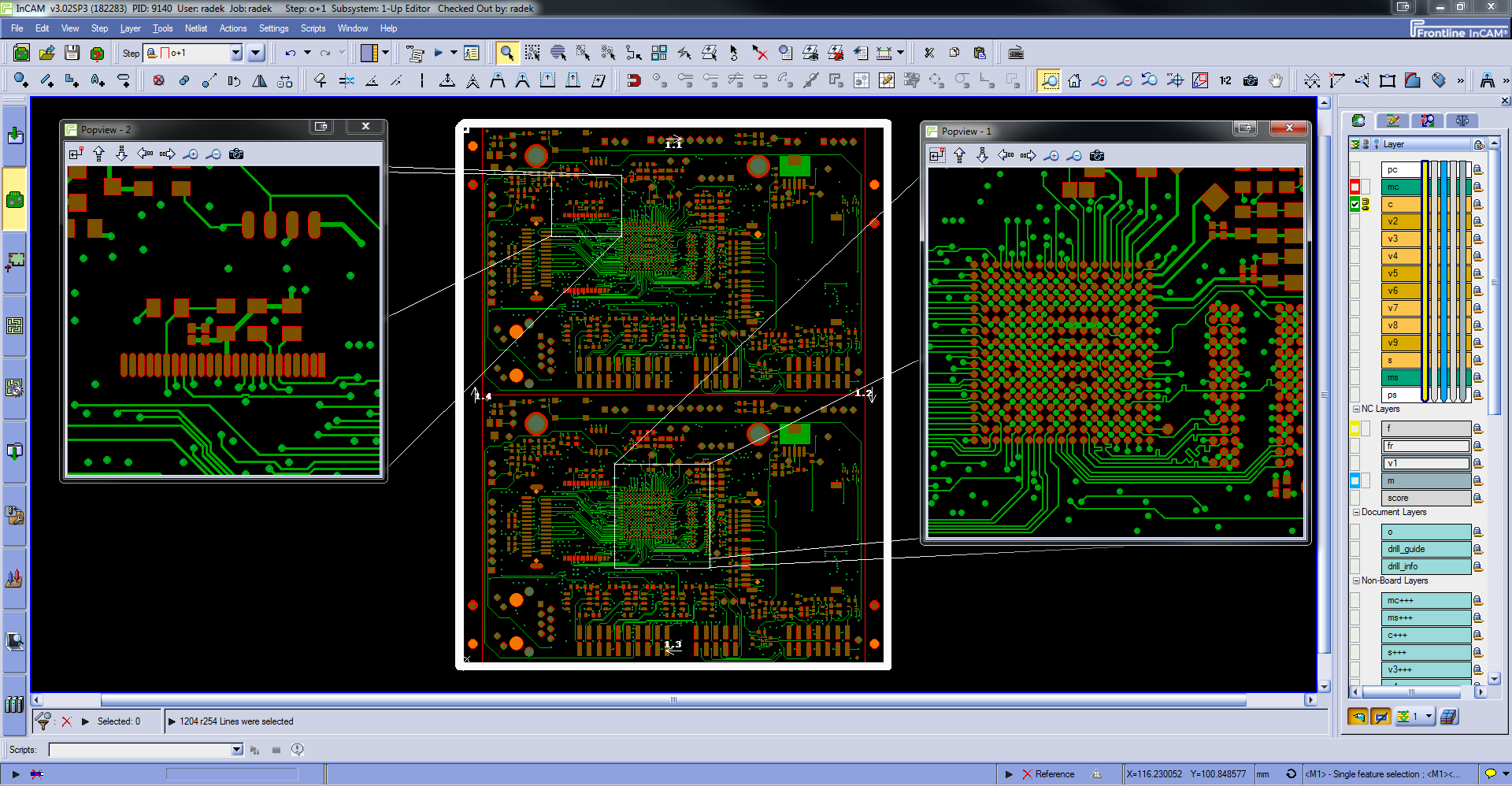

InCAM

InCAM Pro

InCAM Pro by Frontline is a state-of-the-art CAM software designed for efficient data processing in PCB manufacturing. With its modular structure and support for the ODB++ format, it optimizes each step of the processing workflow, saving time and increasing accuracy.

This powerful tool surpasses competitors by enabling parallel processing of multiple tasks in the background, extended RAM utilization, and support for multi-core processors within a 64-bit architecture. Key features also include collaborative processing by multiple users simultaneously and advanced DFM analyses that accelerate and refine data preparation. InCAM Pro offers a high degree of personalization—users can customize keyboard shortcuts, menus, and the workspace, enhancing user comfort and reducing processing time.

A significant advantage is its integration with direct imaging devices and AOI optical testers, streamlining the transition from design to production. With a wide range of optimization modules and a focus on HDI boards, InCAM Pro meets the most demanding requirements of modern PCB manufacturing.

InStack

InStack by Frontline is a powerful tool for designing multilayer PCB stackups, offering engineers the flexibility to consider a wide range of criteria to meet customer requirements.

Beyond basic parameters, users can easily configure core types, insulation distances between layers, and select different materials for each board segment, enabling the creation of hybrid stackups that optimize performance.

A key feature of InStack is its ability to incorporate impedance requirements directly into the stackup design process. By using the InSolver module, which leverages HyperLynx® technology from Mentor Graphics, InStack optimizes stackups to meet impedance specifications and calculates necessary modifications to trace widths. This ensures precise impedance control, critical for signal integrity, and reduces the need for costly revisions later in the design process.

InStack’s intuitive interface makes it easy for engineers to adjust and optimize designs quickly, saving both time and resources. This makes it an essential tool for designing high-performance PCBs with both electrical and mechanical requirements in mind.

Helios NEPHRITE

The ERP system HELIOS Nephrite automates the control and progression of printed circuit board production from customer data entry to the dispatch of finished boards. The production process involves the automated loading of specific programs for controlling the production line, drilling machine, press, milling machine, or CNC.

The production staff confirms the completion of work at individual production stations by scanning the barcode of the specific operation, and this information is transferred to the next workstation for processing scheduling. Each order has precise information regarding the start and end of the operation process. The work performed is also linked to material planning and the issuing of materials for production